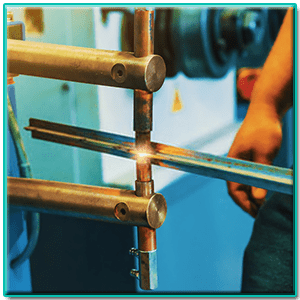

Folks get confused that when there are TIG or MIG welders, what is the actual potential need of spot welders? The answer is quite obvious that you may get stuck while welding overlapping thin sheets of metals using TIG or MIG welders, therefore, the innovation of spot welder paved the way.

Folks get confused that when there are TIG or MIG welders, what is the actual potential need of spot welders? The answer is quite obvious that you may get stuck while welding overlapping thin sheets of metals using TIG or MIG welders, therefore, the innovation of spot welder paved the way.

Typically, spot welders are widely used in industries like automobile, electronic application and battery manufacturing – not only this but skilled professional such as dentists and jewelry makers are also used spot welding in their respective fields.

Considering the fact that a spot welder is a simple machine with a few functions unlike regular welders, certainly, it is much easier to learn and use.

In any way, spot welder is the finest innovation that generates tiny weld with appropriate heat to fuse metals together from both ends.Since it is intended to melt small area of the two composed metals so that’s why filler material is not needed.

Typically, spot welders come in simple design as it is essentially designed and made for a specific function only.

But we should not overlook the cocky fact of the factor ‘market competition’ because of this there is a pile of a variety of types available in spot welders. Which one is the best fit for your need, is the query we are going to address here in a while.

We have invested enough time researching on worth mentioning spot welders and bring to you spot welders reviews based on facts and customer reviews.

We have high hopes that this review will certainly help you make an informed selection while choosing the right spot welders.

Although spot welders are functional-specific engineering tool but you should need to know at least a bit about them such as different types, specification, safety features etc. to avoid any mishap. To feel at ease do check out concise knowledge and buyer’s guide on spot welders mentioned below.

Different types and varieties in spot welders can make things difficult sometimes especially for those who don’t have sound knowledge about the equipment.

To avoid this to happen we have compiled up a list of top 10 best spot welders, which you can buy. We have included regular and portable spot welders both in the list to satisfy all our readers well.

We make sure you get everything entirely stable and fair so you can finally end up with the best one in your hand.

Let’s not waste any further time and heading directly to spot welders reviews:

Table of Contents

- 1 Top 10 Best Spot Welders (2024 )Unbiased Guide

- 2 1. Stark Professional Portable Spot Welder -Editor’s Choice

- 3 2. Mophorn 737G Spot Welding Machine -Best For the Price

- 4 3. Lenco Autobody Dual Spot Welder – Best for the Money

- 5 4. (Generic) Electric Spot Welding Machine -Affordable

- 6 5. OEM TOOLS 24891 120 Volt Spot Welder -Most Expensive

- 7 6. Sunkko LED Dual Pulse Portable Spot Welder

- 8 7. LiRong Ping 709AD Spot Welding Machine

- 9 8. Solary 4200A Spot Portable Spot Welder

- 10 9. YaeCCC 737G Battery Portable Spot Welder

- 11 10. Profab Electric Spot Welder

Top 10 Best Spot Welders (2024 )Unbiased Guide

| Name | Feature | |

|---|---|---|

| Stark Professional Spot Welder (Editor’s Choice) | Portable,Simple Lever Function | |

| Mophorn 737G Spot Welder | Dual pulse mode selection | |

| LencoAutobody Spot Welder | Solid state timer, Single Phase | |

| (Generic) Electric Spot Welder | -- | |

| OEM TOOLS Spot Welder | Welds uncoated stainless steel | |

| Sunkko Spot Welder | One or two pulse welding mood | |

| LiRongPing Spot Welding Machine | 2 in 1 welding pen | |

| Solary Spot Welding Machine | Dual-function welding contact tips | |

| YaeCCC Spot Welder | Controlled by microcomputer | |

| Profab Electric Spot Welder | Dual voltage, 14 gauge capacity |

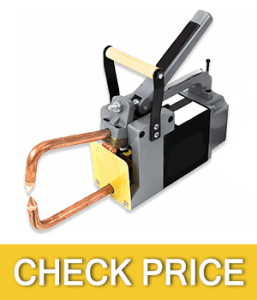

1. Stark Professional Portable Spot Welder -Editor’s Choice

The list top is also taken by the top-rated spot welder by Stark USA and tell you the fact that it is one of the renowned companies in the market for welding equipment.

The list top is also taken by the top-rated spot welder by Stark USA and tell you the fact that it is one of the renowned companies in the market for welding equipment.

By Stark USA this single-phased spot welder is one of the popular and demanding welding machines as it makes spot welding easier to everyone.

If you are a beginner in spot welding this portable professional spot welder is highly recommended. Before getting on the features directly, it is right to say that we expect a bit much with this pro due to its popularity and high demand.

Whereas, the unique design & air-cooled welder is competent to make strong weld instantly that really makes it extraordinary in away.

It does not matter if you deal with different types of materials as a welder; the Stark Professional Spot Welder is designed to serve you in this context.

It offers quick welding for a variety of materials as well as cast iron and steel even you can weld stainless steel sheet and uncoated mild as well.

This stark professional welder is undeniably similar to the same series model in terms of design and features the only difference these two versions share is running on the different voltage of 240 and 120 volt respectively.

If speaking of the technical detail we expressly like the performance of Stark Professional 240v better as it is much competent to weld even thicker metal pieces e.g. two sheets of 16 gauge stainless steel.

Stay with us and take a look at both of pros and cons of this portable spot welder.

- Best affordable option

- Very easy to operate

- The single-phased design makes it adjustment-free

- Runoff with 240volt

- Screw-on replacement tips available

- Simple liver function

- Heavyweight of 20 lbs makes it more stable

- Lack of a plug for power cable

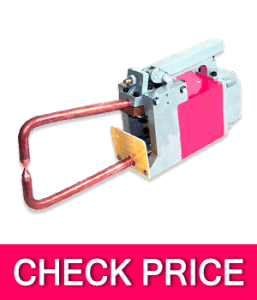

2. Mophorn 737G Spot Welding Machine -Best For the Price

Next on the list, we come up with not so popular, an underrated Spot welding machine by the brand Mophorn.

Next on the list, we come up with not so popular, an underrated Spot welding machine by the brand Mophorn.

As a brand itself no doubt Morphorn is an underrated company which has delivered hundreds of best performing electric equipment and spot welders to this market.

With said, if you expect Mophorn 737G Spot Welder take you by surprise you may be at mistake here a bit.

This model by Mophorn is although budget-friendly and ideal for people who have budget constraint it is the welder only for thinner steel sheets of around (0.03 – 0.2 mm).

Accordingly, it suits those who tend to work light with nickel-plated steel strips likewise it performs great with rechargeable lithium batteries.

Now at this point, you should know all sorts of features of this spot welder makes it worth buying option.

All other matters aside but we highly appreciate its unique LCD panel that will give you a clear display of pulse and current when you would weld using the machine.

You can even adjust from 0 to 99 level current option and dual pulse mode setting with pace efficiently.

What you expect may not be there but what you cannot is right here, intelligent radiator technology is another ultra-advance feature of the unit that’s certainly enhances welding performance to better.

However, the handy spot welder is packed with many advance and top-notch features but some of its flaws are worst. Such as the unit is not in a good deal for welding aluminium and copper also it does not go at all with thick stainless steel.

- Reasonable option good for nickel and alloy

- Efficient LCD display

- Require minimum effort to operate

- Runoff of 110 volts of battery

- Advanced cooling technology prevents the unit from overheating

- Good duty cycle

- Foot pedal welding system

- Best workable for battery packs of all sizes, stainless steel hardware and camera

- Low power machine

- Does not weld thick metal sheet

Read Also , Best Welding Helmet

3. Lenco Autobody Dual Spot Welder – Best for the Money

The professional is on the field now; Lenco Marine is the biggest brand name, known for varieties of category products/units, also one of the popular extravagant brands for spot welders and welding equipment in the industry.

The professional is on the field now; Lenco Marine is the biggest brand name, known for varieties of category products/units, also one of the popular extravagant brands for spot welders and welding equipment in the industry.

Although the big brand has been surprised their customers with their top line of spot welders, exclusively LencoAutobody Dual Spot Welder has gained popularity as soon as it is launched.

LencoAutobody, the top line product belongs to Lenco Marine, intended and designed to serve professionals and hobbyists through it’s beyond the limit features, aesthetics and unique portable design.

One of the other shocking factors is ten times cost in comparison to the competition but features, performance and highest power won the battle anyway.

Before get on in-depth details addressing, you need to know that Lenco Autobody Dual Spot Welder is more than just an ordinary welder – from the build type, it is indeed a result of smart designing although it weighs around 110 pounds its overall construction makes it easier to move around the workshop.

The advantages which cannot let you take your eyes close to this extraordinary unit includes automatic timer setting, protected control panel, tool storage space and finest streamlined built.

Where the other spot welders 6 inches tong for welding, this technological pro offers two-electrode guns with a 5-foot long cable each attached to it to perform easier and powerful autobody panel weld.

Although this dual spot welder is a real pro and favorite but honestly speaking it is not something ideal for beginners as it does not include spot welding tip so keep this factor in mind when making a purchase.

- Highest quality unit

- Smooth mobility possible due to smooth wheels

- 208/230 volts

- Pretty much reach available for cables than the competition

- Very fast, clean and smooth welds

- Weld up to 20 gauge steel

- Hefty price

4. (Generic) Electric Spot Welding Machine -Affordable

On the list, we bring to you simple spot welder which is a good option for single handle operation and light work.

On the list, we bring to you simple spot welder which is a good option for single handle operation and light work.

However the company Generic is not much known as it is the startup brand started to produce welding equipment and so.

Their produced model of spot welder is the simplest machine without frills design; certainly, it is intended for a single function.

Although the unit is easy to use while the major flaw we think of, is the lacking of additional features which can make it a more desirable option.

Design wise it is fine while functioning involves putting the metal between the tongs and simply lever down to perform weld. Performance-wise it is a fine option while with this unit you can weld the metal sheets of thickness 1/8 inches.

It is a bit disappointing that you need to adjust the unit in terms of differentiating the distance within the tongs’ tips which help you with welding different thickness of metal separately.

But the major problem occurs when the user feels issues while adjustment as the same happened with us during testing.

At the same time, the device requires a plug into standard 110volt electric circuit so the user will not need to worry about enough power supply.

We hardly had any complaints about the performance because it makes small weld rapidly which are not clearly visible. But sill the device lacks extra features and versatility.

- Simple design

- Runs on 110v power supply

- Made for a single operation

- Adjustability for metal thickness is difficult

5. OEM TOOLS 24891 120 Volt Spot Welder -Most Expensive

The spot welder 24891 by OEM tools is from the series of impressive spot welders, although it is a bit pricey in comparison to its solid competition it offers great for the price.

The spot welder 24891 by OEM tools is from the series of impressive spot welders, although it is a bit pricey in comparison to its solid competition it offers great for the price.

Speaking of the company, OEM Tools does not need any introduction as it is one amongst the biggest fish of the market, you know what I mean? Jokes apart the brand is pretty much popular and known as a quality guaranteed brand.

According to the test we conducted we feel it is a larger than the welders we have tested that makes it a bulky machine if you feel it is ok then you’re good to go.

When it comes to operation and performance this unit is quite easy to operate and no doubt a solid device offers good performance.

Also, its adjustable 6 inches tongs provide you enough reach to the working station. The unit can be a good option for both beginners and professionals.

Besides,it’s proposed replacement tips for tongs to help to increase the machine’s life. Also, users can easily swap out current tips simply by unscrewing and screwing the new on the same place.

The spot welder is well functional with the combined thickness of 1/8 inches, can be used on galvanized or stainless sheet steel & uncoated mild.

Altogether this spot welder is on the advantageous side but what really made us unhappy is that its similar-sized competitors on the market are less in cost and size.

It would have been better if they added some standout feature that makes it enough prominent and dominating.

- Requires 120-volt input power

- Replacement tips and 6 inches tong

- 5A output current

- A good duty cycle of around 50% at 1.5kVA

- Large in size than similar models

6. Sunkko LED Dual Pulse Portable Spot Welder

The Sunkko 788H Dual Pulse Spot Welder is the most versatile and all-in-one spot welder on the market. The Sunkko is the reputed company, well-known for its high-end electric and welding product line.

The Sunkko 788H Dual Pulse Spot Welder is the most versatile and all-in-one spot welder on the market. The Sunkko is the reputed company, well-known for its high-end electric and welding product line.

Sunkko is one of the brands never compromise on performance and the thing which is like the cherry on top is its reasonable cost range that what justifies the superb factor for the unit.

Sunkko788H is the welder precisely engineered along with various high-tech features which help you accomplish required welding work with extra ease.

On the performance level the device really stands out among its closest competition but we loved the most about the unit is having high-end features which are not even available in many top-notch devices so far.

This extraordinarily crafted multipurpose machine can notch up the current level up to 800 amps so that you can easily and quickly assemble 145000 to 18650 battery stack.

Surprisingly the machine offers ten current settings to choose from while its adjustable voltage range (4.2-32V) is also great and comfortable to weld nickel-plated steel sheet with the thickness ranges from 0.05m to 0.2mm.

At the same time, the smart welder features the most critical factor precision to perform weld and get the most out of it.

Also, the features like foot pedal welding and push-up welding are bang on that improves the accuracy of welding with utmost comfort.

Other than battery assembling process we even used it for battery charging and testing, along with port there is a digital display as well which assist you with charge level.

- Premium-quality welding machine

- Loaded with features

- Best device for the price

- Provide perfect steel sheet welds in just a few minutes

- Current, power and pulse can be easily adjusted

- Could have better with the USB charging port

7. LiRong Ping 709AD Spot Welding Machine

Earlier on the list, we have tested so many before but no one is such new, LiRongPing Spot Welding Machine is new in the market.

Earlier on the list, we have tested so many before but no one is such new, LiRongPing Spot Welding Machine is new in the market.

We somehow glad that tested this one; this should be the one amongst the best quality spot welders on the market. Although it is not really cheap but you will certainly get some cutting-edge features for the cost.

With all its ultra-high-tech features this is the pro best suitable for varieties of application and multipurpose working.

Speaking of the construction and performance, this device has strong and stable built, crafted smartly to help with great performance, this is what the unit does.

We find it a worthy option to all those seeking for something extraordinary and versatile when it comes to welding, power, pulse and current.

When it comes to features, some of them are jaw-dropping like 2 in-one welding pen, is convenient for hand-held while the double click needle balances spring pressure and solder joint very well.

In this way, it gives you safer welding whereas the solder joint distance can be easily adjusted. Not just this but the unit offers 3.2 KW instantaneous high power welding whereas the pressure regulator adjusted according to material thickness during welding.

Although pricey, the all-in-one welder is certainly one of the best options for people who want their spot welding efficient and accurate in less time with all featured-comfort.

With all manners, it is, of course, a worth trying device that hopefully end up making you happy and satisfied.

- High-quality construction for high-quality weld

- Powerful welder

- Fixed welding tips

- Dis touching automatic welding

- LED lights function

- Two-in-one welding pen

- Loaded with accessories

- Expensive

- Not suitable for beginners

8. Solary 4200A Spot Portable Spot Welder

Now let’s jump on the best in category spot welder, here comes the industrial level spot welder Solary 4200A Spot Welding Machine belongs to most famous company Solary.

Now let’s jump on the best in category spot welder, here comes the industrial level spot welder Solary 4200A Spot Welding Machine belongs to most famous company Solary.

Let me be fairly honest the brand which is famous all around the world cannot just produce anything that disappoints customer in any way; this is the same case with Solary Spot welding device.

If you are wondering what solary is up to this time with Solary Spot welding machine then let us tell you the unit will blow you through its welding performance, features, power and facilities.

Whereas the device is great suitable for many tasks but genuinely intended and crafted to use mainly for car dent repair.

One cannot expect anything better when it comes to performance;since machine offers epic current of 4200A which is far more than sufficient for welding any spot.

The welding machine comes at a modest cost but what balances it that for the modest price you end up with numerous cutting-edge features such as dual function tips, pre-programmed time setting, adjustable current settings etc.

The solary spot welder is aimed for those who want perfect welding equipment, can be used for a variety of tasks as well as heavy-duty welding tasks.

Its build-in copper built voltage transformer is enough dexterity to withstand excessive voltage output with a heavy load.

- Best quality machine suitable for multiple welding tasks

- Repairs car dent without damaging colour

- Availability of variable time and current settings

- 230 and 400-volt input voltage

- Suction slide hammer set

- Dual side spot welding

- Thermal protection

- Wheels for easy mobility

- Does not work well on an uneven shape

- Bit expensive

See Also , Lotos ltp5000d Red vs Brown

9. YaeCCC 737G Battery Portable Spot Welder

If you are in search of best battery welder in affordable price then YaeCCC brought you the finest solution, YaeCCC 737G Battery Spot Welder is the perfect solution for battery spot welding.

If you are in search of best battery welder in affordable price then YaeCCC brought you the finest solution, YaeCCC 737G Battery Spot Welder is the perfect solution for battery spot welding.

The prominent company YaeCCC could not take the chance of throwing something insignificant in the market, they tried every possibility to make YaeCCC 737G Battery Spot Welder a big hit.

The company has surprised the consumer by the build quality of the device also equipped with smart-tech features and is pretty much competent to satisfy everyone.

On the performance level, we will rate the machine 8 out of 10, that’s quite impressive if we compare it with the competition.

Coming to the technical stuff of the device, the unit offers you 0 ~ 99 levels current setting and dual pulse mode selection that gives you convenient, efficient and safe welding experience with the super reliable spot.

Additionally, with the same setting adjustability, the unit performs perfect nickel strip weld with the thickness ranges from 0.05 ~ 0.2mm.

One thing I do not like about the machine is that you need to use microchip for precision controlling current so that you can weld in precision; precision is the most vital part of welding which had to be engineered very well in the unit.

Other than this we are fine with the welding machine as it offers a rare feature of controlled the device using a microcomputer.

- Good quality machine

- LED display panel

- Welding power can be adjusted easily

- 110-volt input voltage

- Best applicable for hardware to process, charging battery packs, button cell leads etc.

- Fine work cycle less than 20 times in a minute

- Rather substantial as compared to similar competition models

10. Profab Electric Spot Welder

Lastly, on the list, we come up with the commercial spot welder, ProfabElectric Spot Welder is although intended, designed and crafted for commercial-use but still best functional for a home hobby shop.

Lastly, on the list, we come up with the commercial spot welder, ProfabElectric Spot Welder is although intended, designed and crafted for commercial-use but still best functional for a home hobby shop.

Honestly, the claim of fame of the Profab Electric Spot Welder is not its top-notch features, ultra-high efficiency or welding performance but it is a hefty price.

No wonder the device belongs to the extravagant and breakthrough line of Profab brand is an outstanding tool for spot welding but still, 25 times price tag to other competition is beyond any justification.

If you are wondering it swallow gold, no it’s nothing like that, but yes it offers some great features to deal with during spot welding.

Talking about the features makes it the most versatile machine like dual voltage (220v/440v), up to 14 gauge capacity and single phased electric welder, altogether making it ideal for general and heavy-duty application.

Also, the maker used modern technology PX1600 plus control, it mainly a digital touch pad which enables users to adjust power ramp, squeeze time, auto-repeat, pulse welding, weld power and weld time.

Arms of the machine can be adjusted to give you throat-like depth ranges from 15 inches to 29 inches while the tips are adjustable up, down and 45-degrees of angle.

Let’s peek into a little deeper into the plus points and cons to get you a better and quick idea about the machine.

- Modern high-tech design

- Electric foot pedal

- Précis weld control adjustment

- Water-coated arms and tips

- Equipped with an efficient cooling system

- Too much expensive

- Not portable

- It needed 240 volts of electricity

Best Auto-Darkening Welding Helmets under $200

Buyer’s Guide – Things You Should Know Before Selecting Right One for You

Before getting on any conclusion, firstly you need to take a look at the details and information we presented.

We have come up with all the basic information and detail regarding spot welding and spot welders to help you enough aware of choosing the right one for you.

Most of the spot welders share pretty similar basic design and operation. But there are some notable differences among different types of spot welders other than the cost of course.

In this buyer’s guide, we concisely address those differences, which help you make the right purchase.

Important Factors to address

- Types of machine

The market is carried mainly two forms of spot welding machines whereas the machine’s design is determined by the work type and workplace.

Type one is considered as stationary machines that are heavy and bulky in size which is harder apparently to operate. However, they are enough powerful and ideal to used for thicker metal sheets as compared to another type.

As all know the benefit of portability, this second type of spot welding equipment is perfect to take with you anywhere.

Portable spot welding machines give you an extra advantage especially for repairing work; certainly, its handy factor is bang on comfortable to go around even farthest.

But you cannot expect portable machines to work fine on the thick materials same as the stationary machine does.

- Power supply

Here comes another major consideration power, the power supply is not just a factor but it is sort of decisive factors that really matter for the machine’s capabilities.

There are many of the welding devices can plug into standard voltage circuit of 110v, although there are some require 240volt circuit.

It is necessary to understand this basic need and manage purchase according to the management of electricity supply you have.

Some stationary welders require sufficient power supply so you will need to prepare a generator of around 400 volts.

- Isolator fuse

It is a feature mainly offered in good spot welders and is a voltage surge protection.

- Spot current

Spot current describes the weld quality of the machine, the higher the spot current number of the machine shows its better weld quality.

- Operating factor

It is better to define as duty cycle while the operating factor of the machine often described on the packaging of the machine.

Having higher operating factor is better as the machine will work the majority in ten minutes and just take 2 to 3 minutes to re-cooperate.

The device with higher current machine offers higher operating factor, together it makes the machine more efficient.

- Secondary vacuum voltage

It defines the quality of priming of the spot welding machine. The measurement of secondary vacuum voltage is taken from device terminals before the application of welding current.

Spot welding process

Mainly there are four terms used for the whole process of spot welding which includes welding, docking, forging and release. The term docking describes when you put two sheets of metals within the electrodes of spot welder.

Welding involves when you apply pressure to both metal sheets, whereas, holding the two metal sheets together is known as forging. Similarly when you release off the pressure and get away the electrodes from the plates is called release.

- Solary 4200A Spot Welding Machine

- Stark Professional Spot Welder

- Sunkko LED Dual Pulse Spot Welder